What would Socrates advise on sustainable specification?

You have probably heard of Socrates.

He was a Greek philosopher from Athens who lived between 469-399 BCE. His method was to challenge people’s firmly held beliefs on any subject through systematic questioning until they became less certain, resulting in a state of open-mindedness.

This ‘Socratic Method’ is defined as a philosophy of doubt and questioning, to arrive at a clear expression of truth. This approach is still relevant today and his method has been applied to the education in sustainability of engineering students:

“One of the more perplexing phenomena in sustainable development is the discrepancy between knowing and acting. Discussing the options to make designs, activities and businesses as a whole more sustainable, often leads to the observation that most people accept rationally that sustainable development is necessary but do not implement it effectively into their actual decisions. Understanding does not automatically lead to proper actions.”

Dimitri van de Kelft and Jan Venselaar

Avans Hogeschool, University of Applied Sciences, Research Group Sustainable Business Operations

An accepted definition of Sustainability by the Brundtland commission named after its chair, Norwegian diplomat Gro Harlem Brundtland is:

“Development that meets the needs of the present without compromising the ability of future generations to meet their own needs.”

Our Common Future, by the United Nations World Commission on Environment and Development

The whole area of sustainability has grown considerably since this definition was constructed in the earlier part of the 21st Century. It is fair to say it has become associated with many other factors, but its original intention could be translated as ‘Not taking more than our fair share’.

The Circular Economy

Recycling is not a simple issue and it is now more common to speak of The Circular Economy. This can be a more relevant term when considering manufacturing and specification in construction, a sector that has always been one of the greatest contributors to waste.

‘A circular economy is based on the principles of designing out waste and pollution, keeping products and materials in use, and regenerating natural systems.’

It makes perfect sense to ensure materials that have been taken from the earth are used repeatedly and not dumped in a landfill or incinerated after a single use. But in reality, there isn’t always a sustainable choice with products used in construction. Nevertheless, we can adhere to the principle of specifying materials that can be endlessly recycled.

It is not too much of a stretch to argue that this is a Socratic approach.

This has been the case with MDF until relatively recently. The UK produces around 1 million tonnes of this material every year and for the most part, it has been used once and then disposed of. Recyclable variants of MDF have been developed and are now in use.

Socratic Specification

When specifiers consider building products and materials, there are many issues to consider within the overall needs of the project. Construction materials are used because of specific properties. This can be about strength, lightness and ease of installation. It can also be about fire resistance, water tightness, durability and public health concerns. Most recently in the current pandemic, there has been a major area of focus - hygienic properties. The most striking example of this was the urgent and rapid construction of the Nightingale Hospitals across the country.

This is a perfect example of where a reasoned discussion and rational examination can lead to highly sustainable materials being used. Materials that fulfil the critical need for hygiene in caring for desperately sick people and protecting the dedicated front-line workers in the NHS.

BePlas are a specialist manufacturer who produce anti-microbial wall and ceiling products that halt the growth of not only bacteria, but organisms, protozoa, fungi and viruses. This antimicrobial additive is not a coating but is incorporated into the entire product. BePlas products are crucial, but they are also sustainable, as they are made from 100% recyclable PVC.

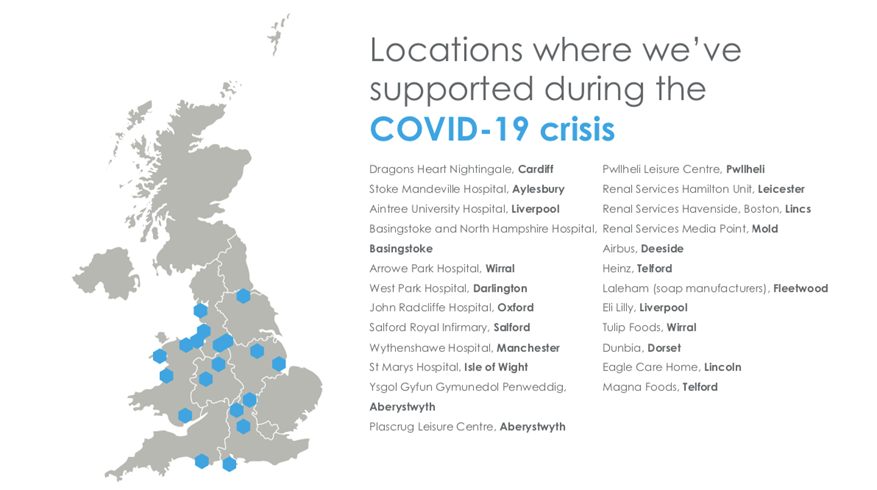

Beplas was a leading supplier in the creation of the Nightingale Wards up and down the UK.

Products that will be actively protecting people in all kinds of environments, especially the most vulnerable, for decades to come.

Specifying materials that meet the needs of the present without sacrificing the future via circular economy thinking is a ‘Socratic Good.’

Socrates would be proud.

NBS Specification

NBS Specification Book a CPD

Book a CPD